ESI

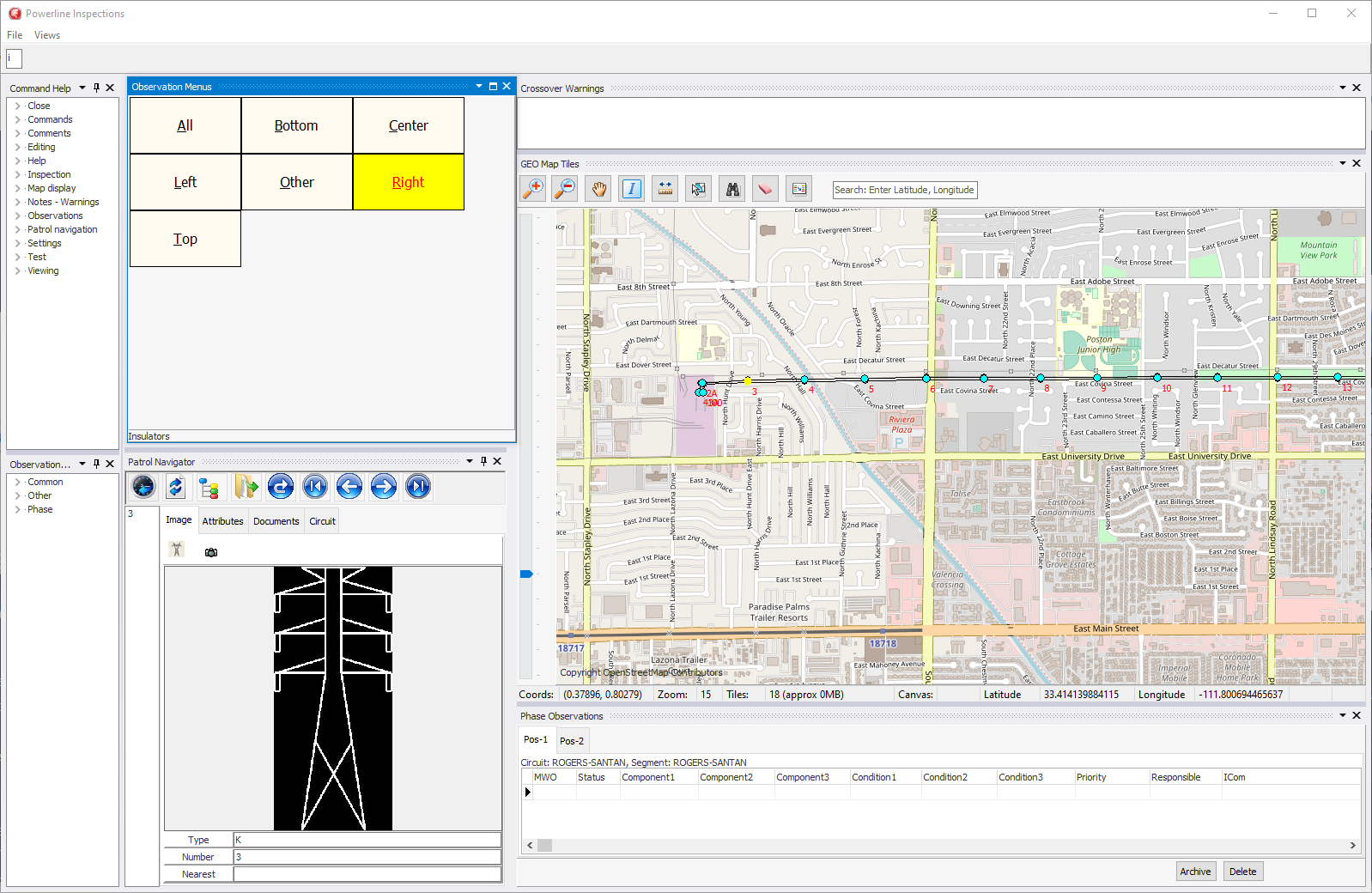

Electric System Inspection Software

Streamlining Inspection and Maintenance of Electric Systems!

ESI is a GIS/GPS based application that maximizes the value of field inspections and performs outstanding work management capabilities.

ESI gets your company up and running quickly on a flexible system that delivers a key component of reliability centered maintenance (RCM) at a fraction of

the cost of more costly maintenance and inspection systems.